3D Car Printing

March 7, 2017

Three dimensional printing has been a really big topic this year, with new funds such as 3d printing food, artwork, buildings, and more, but most importantly, automobiles today are being created with the works of 3D printers by Local Motors engineers and designers are working around the clock to develop a 3D-printed car that exceeds FMVSS (Federal Motor Vehicle Safety Standards) by 2017.

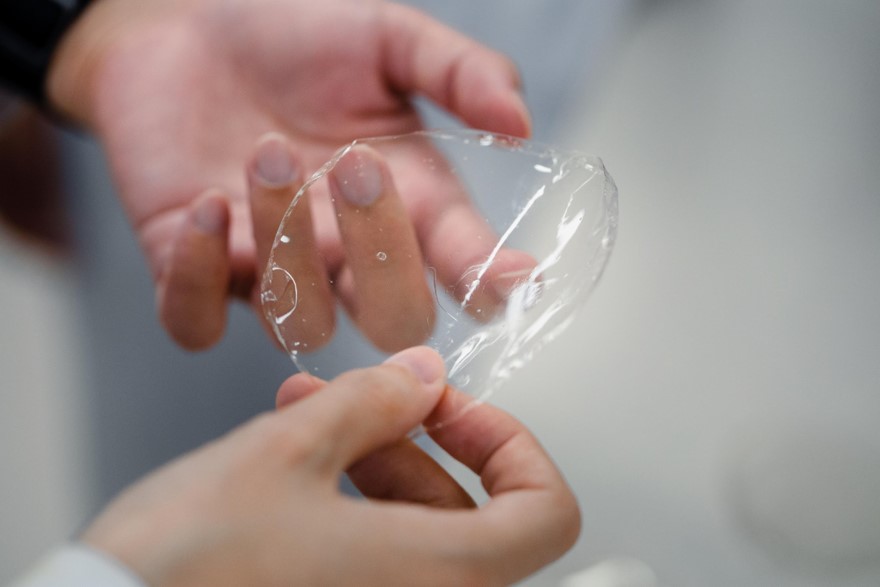

Local Motors are working with some incredible partners to bring the 3D-printed car to market. A key advantage of 3D printing is that it removes constraints found with traditional manufacturing, reducing cycle time and production costs. Most recently, Local Motors has partnered with IBM (International Business Machines) to integrate 3D printing into the 3D-printed car, Siemens’ Solid Edge to provide CAD (computer-aided design) modeling, IDEO (Innovation, Design Engineering Organization) to renew Local Motors Labs, and SABIC (Saudi Arabia Basic Industries Corporation) to improve materials.

The LM3D is one of the first 3d printed cars to be created this year. Roughly 75% of the LM3D is printed. Local Motors goal is to consolidate as much of the traditional bill of materials into a single, 3D-printed piece as possible, eventually making about 90% of the car using 3D-printing. Nearly all of the body panels and chassis are 3D printed on the LM3D. Local Motors are continually testing new types of materials and different blends for additive manufacturing. As of now, they are using a blend of 80 percent ABS plastic and 20 percent carbon fiber. The design was chosen by the Local Motors community and a judging panel (including Jay Leno) from over 200 designs from a design challenge hosted on the Local Motors open innovation platform, called Open IO. Designer Kevin Lo of Portland, OR is the creative mind behind the design. It was chosen on July 7th, and the build was completed on September 18th. Taking just over two months from design to prototype, Local Motors built a 3D-printed car at unprecedented speed.

The LM3D was built with a focus on further optimizing the construction methodology of Direct Digital Manufacturing. With the LM3D series, early tests show promise that all crash testing will be complete by the end of 2016 including all certifications needed to get 3D-printed cars on the road. In fact, our goal is to make 3D-printed cars safer than traditionally manufactured cars. In order to ensure compliance, but more importantly, consumer safety, the underpinnings of the vehicle throughout the series will remain the same. However, Local Motors plan to offer a wide range of customizable, aesthetic features that are only possible through DDM and 3D printing. Cars could look radically different but be built on the same platform.

People will be able to place a deposit on an LM3D via a crowdfunding campaign, expected to launch in Q2 of 2016. Retail purchase will be available later in 2016.